Manufacturing has long relied on machines and automation to drive productivity, but artificial intelligence (AI) is transforming the factory floor in unprecedented ways. No longer confined to isolated robots performing repetitive tasks, AI now sits at the heart of production planning, quality control, supply‑chain management and product design. For manufacturers facing volatile demand, supply shocks and relentless pressure to cut costs, AI offers a path from basic automation to full‑scale optimization.

Ready to implement AI?

Get a free audit to discover automation opportunities for your business.

Why AI matters for manufacturers

Factories today operate under enormous pressure. Equipment downtime can cost a plant hundreds of thousands of dollars per hour, and an unexpected shutdown can ripple through an entire supply chain. At the same time, customers expect consistent quality, faster delivery and sustainable practices. Recent surveys show that around 72% of manufacturers report reduced costs and improved operational efficiency after deploying AI, with roughly half citing greater visibility and responsiveness and about 40% seeing improvements in process optimisation. These results underscore why AI is moving from pilot projects to core capability in modern factories.

From automation to optimization: key AI use cases

Predictive maintenance

Unplanned downtime is one of the most expensive problems in manufacturing. AI‑based predictive maintenance uses sensor data—vibration, temperature, energy consumption and acoustic signals—to detect early signs of equipment failure. Machine‑learning models predict when parts will wear out and schedule maintenance only when needed, reducing unplanned downtime by up to half and extending equipment life. For example, a large automaker used an AI system to inspect robotic welding arms, cutting inspection time by 70% and improving weld quality by 10%.

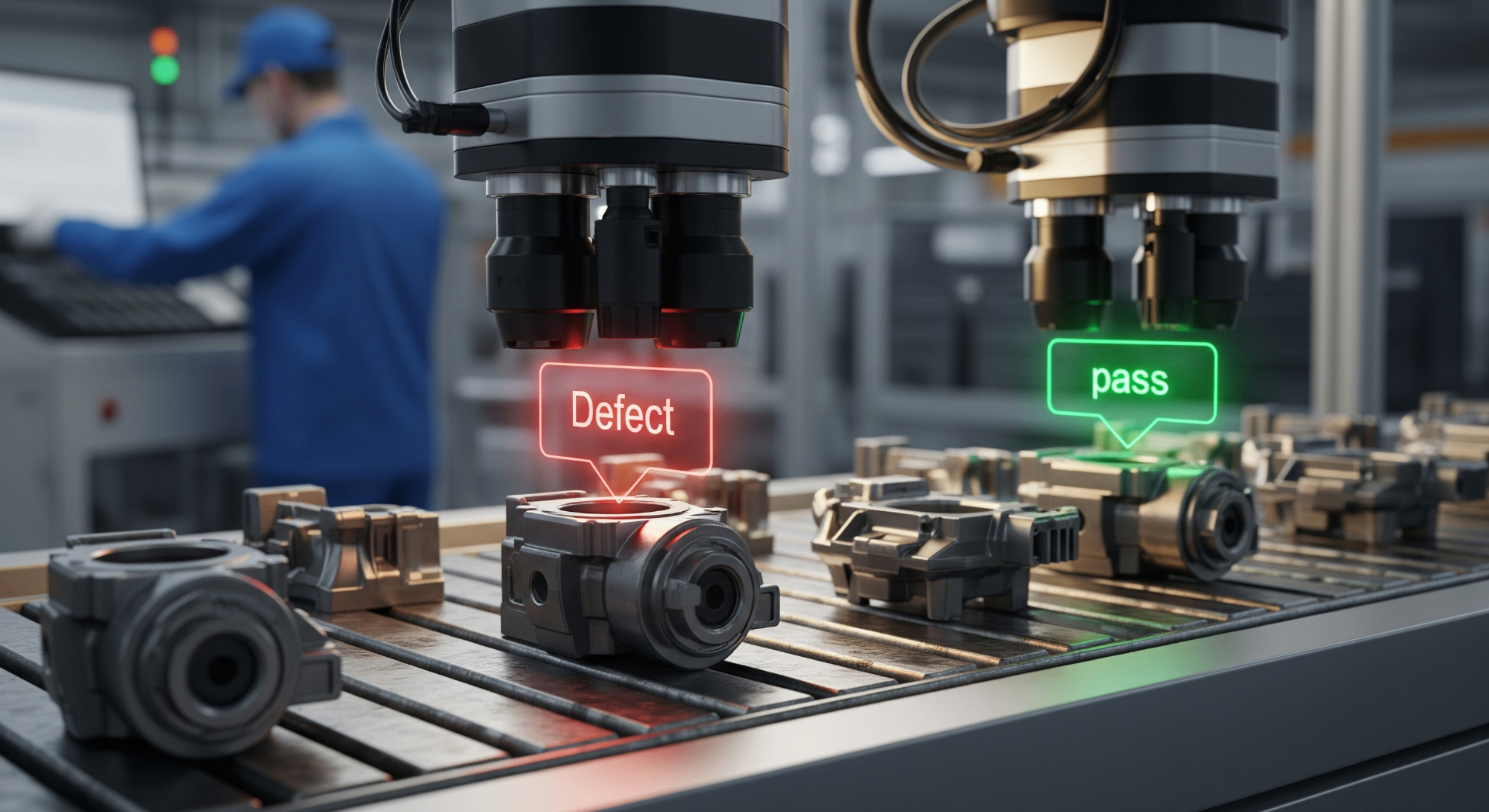

Quality control and defect detection

Computer vision and deep‑learning algorithms now inspect products in real time, identifying surface defects, dimensional inaccuracies and material inconsistencies at high speeds. AI‑powered quality control can achieve over 90% defect detection accuracy and cut inspection costs by about half. Companies like Merck and Schaeffler use AI vision systems to detect defects on pharmaceutical tablets and automotive components, ensuring compliance and reducing waste.

Supply‑chain optimization

Modern supply chains are complex and prone to disruption. AI analyzes historical sales, economic indicators and real‑time signals to forecast demand, optimise inventory and plan logistics. Such systems reduce excess stock, improve delivery times and help mitigate risks. Amazon famously uses AI to forecast demand for hundreds of millions of products, manage warehouse robots and predict weather‑related delays. In manufacturing, similar systems help plants coordinate raw‑material supply and finished‑goods distribution with unprecedented precision.

Robotic process automation (RPA) and cobots

Beyond the physical robots that build and weld, AI‑powered software bots handle back‑office tasks such as data entry, order processing and compliance reporting. RPA reduces administrative costs, improves accuracy and frees employees to focus on strategic work. Whirlpool and Ajinomoto deploy RPA bots on assembly lines and in finance departments, saving hundreds of hours per month. On the shop floor, collaborative robots (cobots) work alongside humans to pick, place or assemble components, boosting productivity while maintaining safety.

Energy management and sustainability

Manufacturing accounts for a significant share of global energy use and emissions. AI‑driven energy management systems analyse real‑time consumption data to optimise lighting, heating and machine operation. These systems cut energy costs and support sustainability goals without sacrificing throughput. Combined with digital twins—virtual replicas of production lines—AI helps manufacturers test changes, reduce waste and meet regulatory requirements.

Generative design and product innovation

Generative AI tools enable engineers to input performance requirements and constraints, then generate optimised component geometries that traditional design methods might miss. This accelerates innovation, reduces material usage and shortens development cycles. Examples include lightweight automotive parts and heat‑exchanger designs that balance strength with efficiency.

Digital twins and simulation

Digital twins are virtual replicas of factories, machines or products. AI and physics‑based models allow engineers to simulate production scenarios, test process changes and predict outcomes without disrupting operations. Digital twins enhance planning, training and maintenance by providing a digital sandbox for experimentation.

Worker safety and hazard detection

AI systems monitor workers on the factory floor using cameras and sensors to ensure compliance with personal protective equipment (PPE) requirements and to detect hazardous conditions. Real‑time alerts reduce workplace accidents and improve safety. Some plants have raised PPE compliance rates from around 70% to over 95% and cut workplace incidents by half.

Fleet and logistics optimization

In manufacturing logistics, AI optimizes route planning, monitors vehicle health and ensures secure loads. Real‑time GPS data and sensor readings help plan efficient routes, predict maintenance needs and reduce idle times. Plants using AI‑driven fleet management have reported fuel savings of about 20%, maintenance cost reductions of around 25% and a 30% increase in on‑time deliveries.

Benefits for manufacturers

Reduced downtime and maintenance costs: Predictive maintenance prevents unplanned shutdowns and reduces repair costs, extending asset life.

Improved product quality: Real‑time defect detection and process control lead to more consistent products and fewer recalls.

Greater efficiency and cost savings: AI optimizes production, inventory and logistics, lowering energy use, labour costs and waste.

Faster innovation: Generative design and digital twins accelerate product development and reduce time to market.

Enhanced worker safety: Hazard detection systems protect workers and improve compliance with regulations.

Competitive advantage: Early adopters of AI report higher profitability, improved customer satisfaction and the flexibility to respond to market shifts.

Adoption trends and market outlook

AI adoption in manufacturing is accelerating. Recent surveys reveal that more than nine out of ten manufacturing executives believe AI is critical for innovation, and about 86% have adopted or plan to adopt AI technologies. Many companies expect AI to significantly affect manufacturing within the next few years. The global AI in manufacturing market, valued at roughly $4.2 billion in 2024, is projected to grow at an annual rate of about 31% between 2025 and 2034. Governments worldwide are investing in AI research and offering incentives to accelerate adoption.

Companies are already seeing financial gains: Kraft Heinz added approximately $30 million to its sales by integrating AI into its supply chain. These success stories illustrate the real economic impact of AI and build confidence that further investment will generate returns.

Challenges and best practices

Implementing AI in manufacturing isn't without obstacles. Firms must address data quality, privacy and integration issues. Workforce readiness is another concern: employees need training to collaborate with AI systems, and management must emphasise that AI augments human work rather than replacing it. Cybersecurity is critical because AI systems often handle proprietary information and are potential targets for attack. Organisations should also ensure fairness and transparency in AI decision‑making to prevent bias and meet regulatory requirements.

Best practices include:

Define clear objectives: Start with specific problems—such as reducing downtime or improving quality—rather than applying AI for its own sake.

Invest in data infrastructure: Reliable, accessible data pipelines are essential for training and deploying AI models.

Upskill the workforce: Train engineers, operators and managers to understand AI outputs and work alongside automated systems.

Partner with experts: Collaborate with AI vendors, consultants or research institutions to fill skill gaps and accelerate implementation.

Prioritize security and ethics: Protect sensitive data, audit algorithms for bias and ensure transparency in AI‑driven decisions.

Conclusion

AI is ushering manufacturers into a new era: from basic automation to holistic optimisation of production, logistics and product innovation. Companies adopting AI report reduced costs, higher efficiency and improved quality. With market growth expected to accelerate over the next decade and real‑world success stories showing significant returns, AI is becoming a strategic necessity in manufacturing. By carefully addressing challenges and following best practices, manufacturers can harness AI to create resilient, responsive and profitable operations.